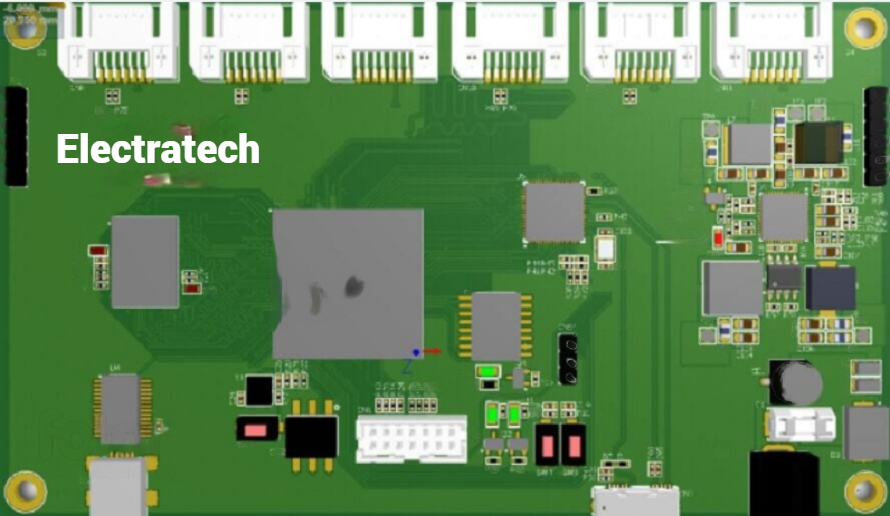

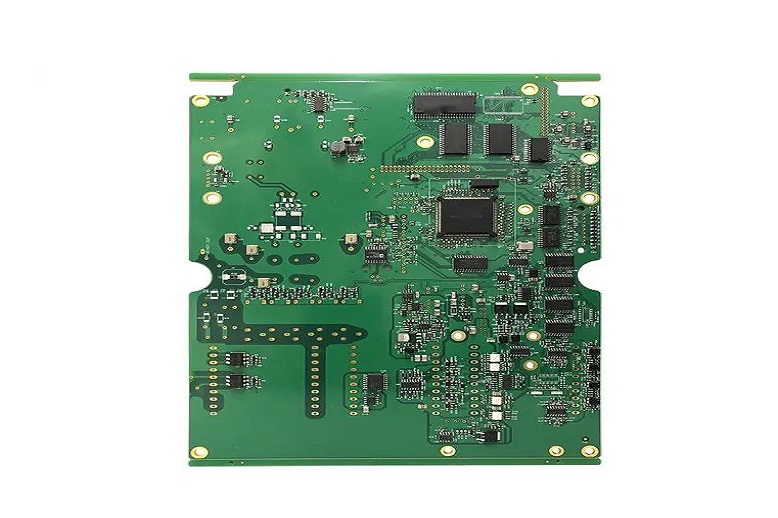

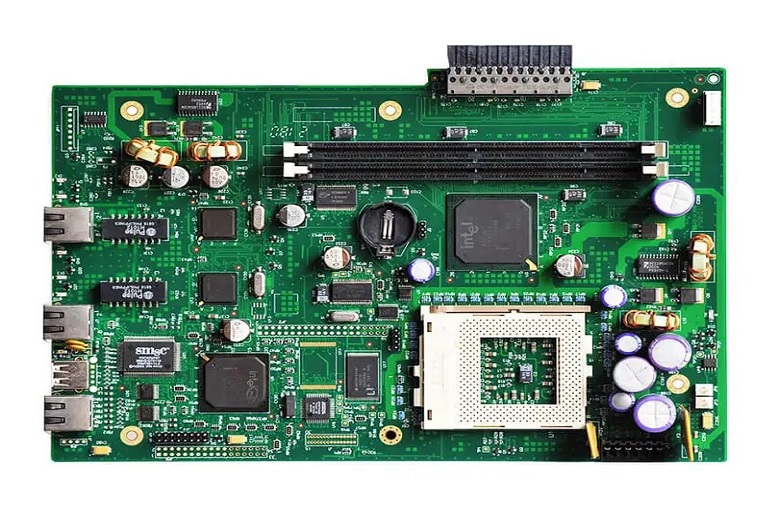

PCB ASSEMBLY (PCBA)

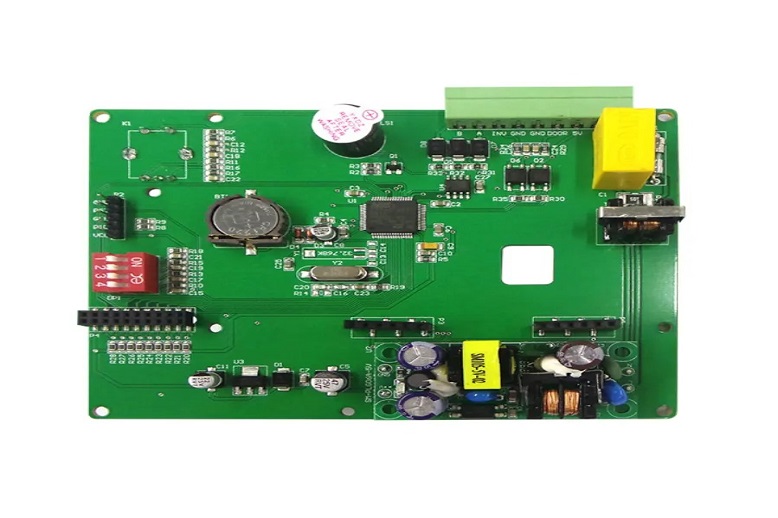

From simple single-sided assemblies to complex densely populated fine pitch and BGA surface mount assemblies, the ElectraTech engineering team offers PCBA manufacturing solutions that are customized using our advanced production equipment. ElectraTech assures with ISO9001-2015 certified quality management systems, IPC Class 1, 2 or 3 standards as per the application. Also protects confidential and proprietary information with a Non-Disclosure agreement with Customers

ElectraTech PCB Assembly Capabilities Include:

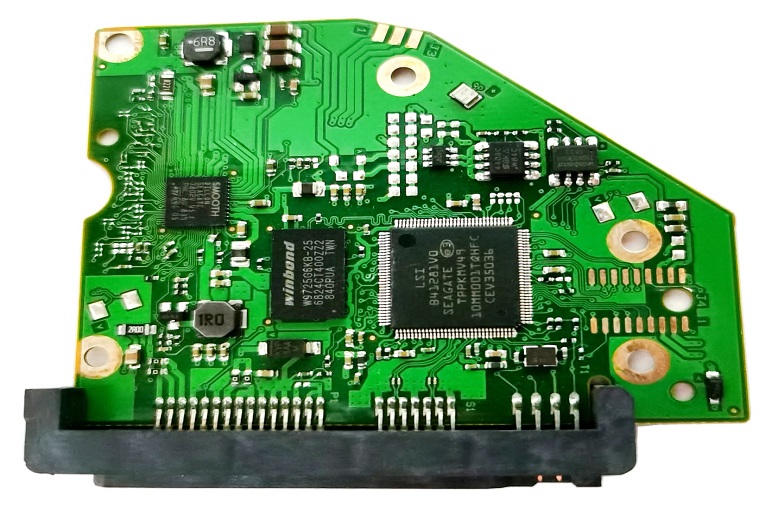

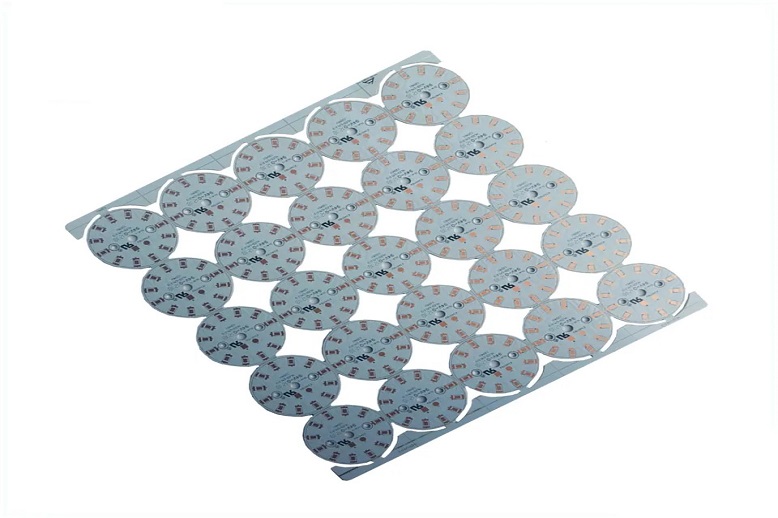

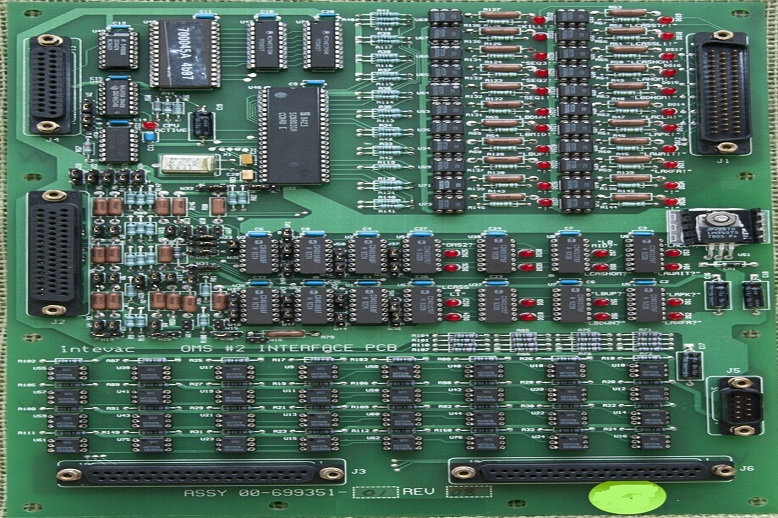

- Expertise in single, multi-layer flexible and rigid circuitry boards.

- In-depth knowledge of various application requirements.

- Proficient in surface mounting, through-hole, and mixed technology.

- State-of-the-art advanced manufacturing equipment.

- Stringent quality inspections.

- Passive components 0201 and higher.

- Active components from 0.35mm pitch.

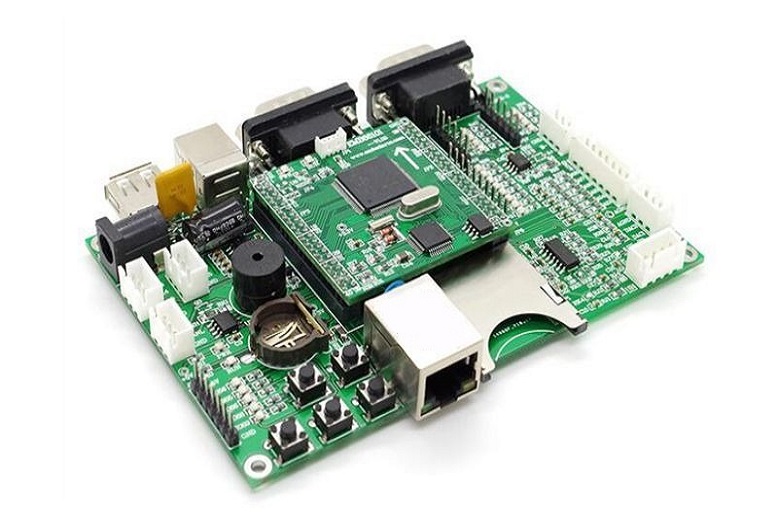

- BGA, micro-BGA, QFN, CSP and any leadless devices up to .35mm pitch assembly with 100% 3D X-ray inspection.

- Solder Type (Lead-free – RoHS).

- Automatic Single- or double sided component placement.

- Visual Inspection, Solder past Inspection (SPI), X -ray inspection BGA Placement-microscope inspection.

Our PCB layout and design experts have decades of experience. Years of experience in the field have enabled us to develop customized products that meet the diverse requirements of the clients Our PCB design team also collaborates with trusted partners of various specialties, ensuring that we always deliver the optimal design for your business—regardless of complexity. Our process is suitable for every industry, as demonstrated by our customers that span a variety of sectors, including automotive, aerospace, military, telecom, and healthcare.

We also ensure timely delivery of appropriately packaged freight to any location specified by the clients. Our range is designed and developed in compliance with the industry norms, using high grade raw material. The PCB routing process is both an art and a science. Using physical wires, you’ll define electrical connectivity between components on a PCB layout.

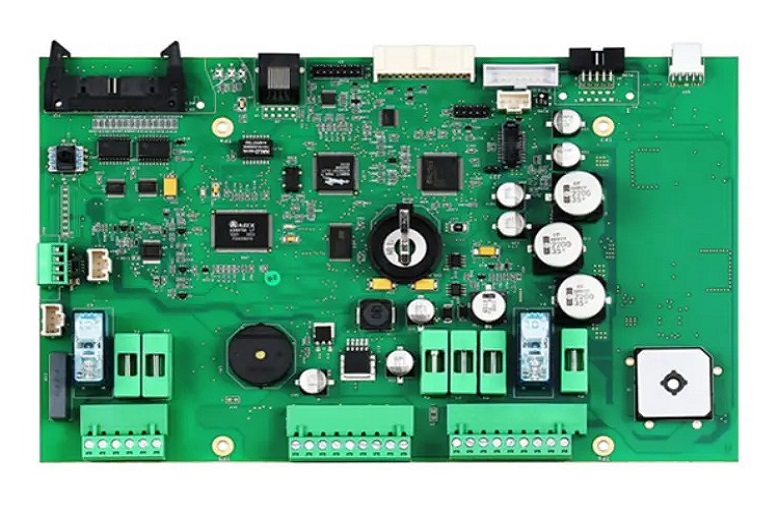

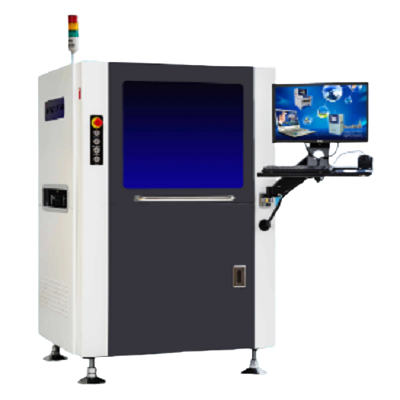

PCB Assembly line

ElectraTech has been striving to acquire local manufacturing capabilities for all kinds of electronic assemblies. For this purpose, we have deployed an automated PCB SMT & THT assembly plant along with rework and inspection systems.

Our Assembly Lines feature with various setups, suitable for different production requirements. The lines consist of below equipment:

- Automatic Stencil Printer.

- SPI (Solder Paste Inspection System).

- High-speed Pick-and-Place Machine.

- 12 Heat-Zone Reflow Machine.

- Automatic Optical Inspection System.

- X-Ray inspection.

- Wave Soldering for THT.

Our automatic screen printer machine performs solder spread process using definite stencils specially produced for each printed circuit board.

SPI machine is able to fix solder paste defects that provides an opportunity to get rid of defected boards before they will be used in production process. While performing this process, we can examine the solder height with 10-micron precision using 3D feature of SPI machine.

Our SMT assembly line equipped with high thermal performance, lead-free reflow oven for Surface mount. devices soldering.

ElectraTech SMT Assembly line equipped with fast smart modular Pick & Place machines these machines can achieve a mounting speed of more than 75,000 CPH and mount components from 01005 to large chips like BGAs and QFPs with high accuracy for IPC class 3 standards.

With our AOI machines, we are able to perform all the final control operations such as detecting soldering defects, wrong position of the components and detecting any errors in the manufacturing process that assures process quality before the boards are moved to the next manufacturing step.

SMT line equipped with the X-ray inspection equipment to scan solder joints inside the components and check for potential defects in a design.

Our THT line consists of high quality with advance technology Lead-Free Wave Soldering machine to provide customers with quality products and THT solutions.